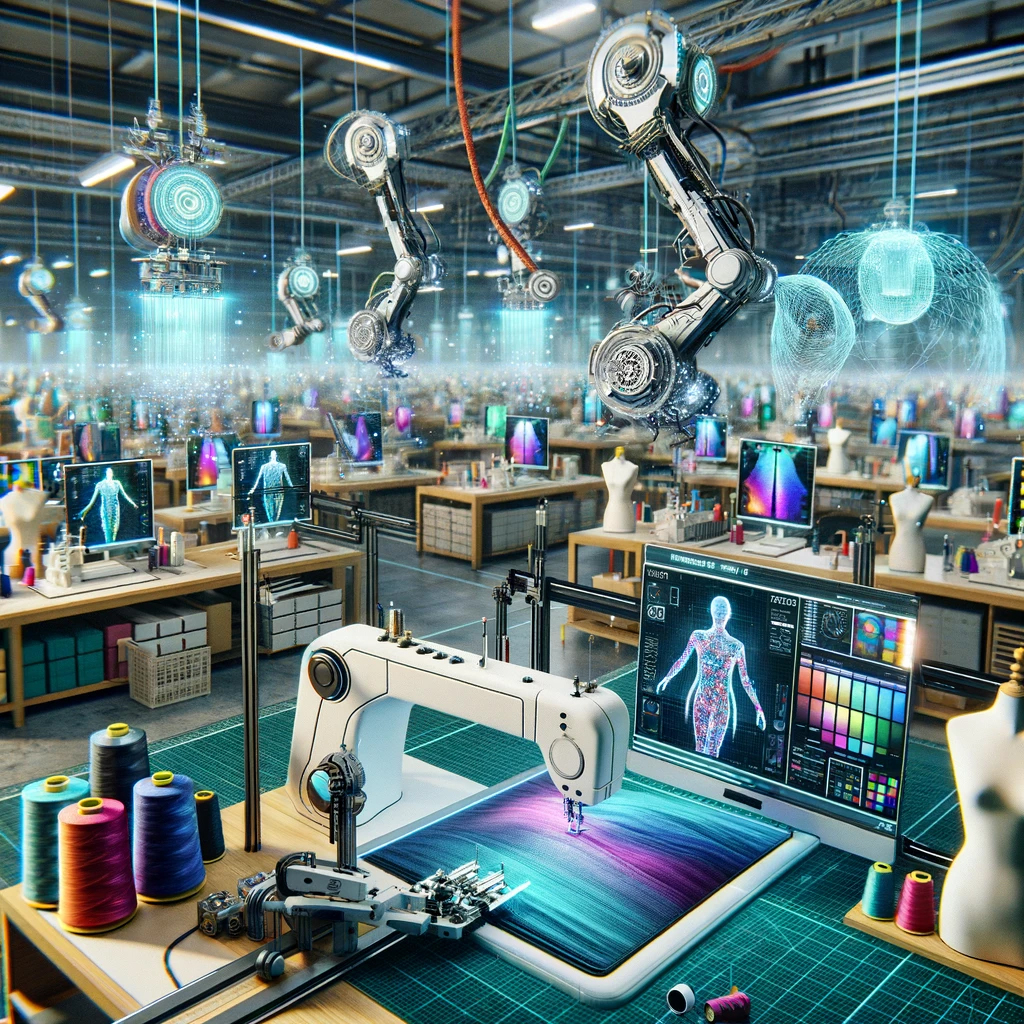

Artificial Intelligence (AI) is reshaping the textile and clothing industry, revolutionizing various aspects of the production process, supply chain management, and customer engagement. From design and manufacturing to retail and customer service, AI technologies are driving innovation and efficiency, enabling businesses to meet the evolving demands of consumers in the digital age.

Enhancing Design and Innovation

AI algorithms analyze vast amounts of data, including consumer preferences, fashion trends, historical sales data, and social media interactions, to provide valuable insights into design preferences and market demands. By interpreting this data, designers gain a deeper understanding of emerging trends, allowing them to create products that resonate with target audiences and stay ahead of the competition.

Automated Pattern Generation

Traditionally, creating intricate patterns for textiles and clothing required considerable time and expertise. AI-driven pattern generation tools utilize machine learning algorithms to automate this process, generating a wide range of patterns quickly and efficiently. Designers can input parameters such as color palettes, textures, and styles, and AI algorithms generate customized patterns that align with their specifications, saving time and fostering creativity.

Virtual Prototyping and Simulation

AI-powered virtual prototyping and simulation tools enable designers to visualize and test their designs in a virtual environment before committing to physical prototypes. By simulating fabric drape, garment fit, and texture variations, designers can identify potential design flaws and make adjustments early in the development process, reducing costly iterations and accelerating time to market. Virtual prototyping also facilitates collaboration between designers, manufacturers, and stakeholders, enabling seamless communication and feedback exchange.

Customization and Personalization

AI technologies enable personalized design experiences, allowing consumers to customize clothing items according to their preferences and specifications. Through interactive design interfaces and configurators, customers can choose fabric types, colors, patterns, and embellishments to create bespoke garments tailored to their individual style and preferences. AI-driven customization not only enhances customer satisfaction but also fosters brand loyalty and differentiation in a competitive market landscape.

Trend Forecasting and Predictive Analytics

AI-powered trend forecasting and predictive analytics tools analyze vast amounts of data from social media, fashion blogs, runway shows, and e-commerce platforms to identify emerging trends and consumer preferences. By leveraging machine learning algorithms, businesses can anticipate market shifts, forecast demand for specific styles or products, and align their design strategies accordingly. Trend forecasting enables proactive decision-making, allowing businesses to capitalize on emerging opportunities and stay ahead of competitors.

Improving Manufacturing Processes

Improving manufacturing processes through the integration of artificial intelligence (AI) has become a focal point for many industries seeking to enhance efficiency, quality, and productivity. AI technologies offer a wide range of capabilities that can streamline various aspects of the manufacturing workflow. One key area of improvement is predictive maintenance, where AI algorithms analyze data from sensors and historical maintenance records to predict equipment failures before they occur. By identifying potential issues in advance, manufacturers can schedule maintenance proactively, minimizing unplanned downtime and optimizing production schedules.

Another significant aspect of improving manufacturing processes with AI is through quality control and defect detection. AI-powered systems utilize advanced algorithms and computer vision technology to inspect products for defects or deviations on the production line. By automating the inspection process, manufacturers can achieve consistent quality standards, reduce waste, and ensure that only defect-free products reach the market. This not only improves product quality but also enhances customer satisfaction and brand reputation.

Additionally, AI plays a crucial role in optimizing production scheduling and resource allocation. Machine learning algorithms analyze data on production demand, inventory levels, and supply chain dynamics to optimize production schedules and resource utilization. By dynamically adjusting production parameters in real-time, manufacturers can respond to changes in demand or supply constraints more effectively, minimizing costs and maximizing efficiency.

Furthermore, AI-driven analytics provide valuable insights into manufacturing operations, enabling data-driven decision-making and continuous improvement. By analyzing data on production performance, equipment efficiency, and quality metrics, manufacturers can identify areas for optimization and implement targeted interventions to improve overall productivity and profitability. This data-driven approach allows manufacturers to identify trends, patterns, and opportunities for optimization that may not be apparent through traditional methods.

Overall, the integration of AI into manufacturing processes offers significant potential for improving efficiency, quality, and productivity across the board. By leveraging predictive maintenance, quality control, production scheduling, and analytics, manufacturers can achieve operational excellence and maintain a competitive edge in today’s rapidly evolving marketplace. As AI technologies continue to advance, the possibilities for enhancing manufacturing processes will only continue to grow, driving innovation and transformation across the industry.

Personalized Shopping Experiences

AI-driven personalization is transforming the retail experience for consumers, offering tailored recommendations, and personalized shopping journeys. Recommendation engines analyze customer preferences, purchase history, and browsing behavior to suggest relevant products and promotions, enhancing engagement and conversion rates. Virtual try-on technologies leverage augmented reality (AR) and computer vision to allow customers to visualize clothing items on virtual avatars, facilitating confident purchase decisions and reducing returns.

Supply Chain Optimization

Supply chain optimization is a critical focus area for industries seeking to streamline operations, reduce costs, and improve overall efficiency. Artificial intelligence (AI) plays a pivotal role in optimizing supply chain processes by leveraging advanced algorithms and data analytics to enhance visibility, agility, and decision-making. Here’s how AI contributes to supply chain optimization:

- Demand Forecasting: AI algorithms analyze historical sales data, market trends, and external factors to generate accurate demand forecasts. By predicting future demand levels, manufacturers can optimize production schedules, inventory levels, and distribution strategies to meet customer demand efficiently while minimizing excess inventory or stockouts.

- Inventory Management: AI-powered inventory management systems optimize inventory levels and replenishment processes by dynamically adjusting inventory levels based on demand forecasts, lead times, and supply chain constraints. By maintaining optimal inventory levels, businesses can reduce carrying costs, minimize stockouts, and improve cash flow.

- Transportation and Logistics: AI algorithms optimize transportation routes, modes, and carrier selection to minimize transit times, transportation costs, and carbon emissions. By analyzing factors such as traffic conditions, weather forecasts, and delivery constraints, AI-powered logistics systems ensure timely and cost-effective delivery of goods to customers.

- Supplier Relationship Management: AI enables businesses to analyze supplier performance, track supplier risk factors, and optimize supplier selection and negotiation processes. By identifying high-performing suppliers, mitigating supply chain risks, and negotiating favorable terms, businesses can strengthen supplier relationships and enhance supply chain resilience.

- Warehouse Operations: AI-powered warehouse management systems optimize warehouse layout, storage allocation, and order picking processes to improve efficiency and productivity. By automating routine tasks, optimizing storage space, and minimizing order processing times, businesses can reduce labor costs and fulfillment times while improving customer satisfaction.

- Predictive Maintenance: AI algorithms analyze equipment sensor data to predict equipment failures before they occur, enabling proactive maintenance and minimizing unplanned downtime. By implementing predictive maintenance strategies, businesses can optimize equipment reliability, extend asset lifespan, and reduce maintenance costs.

- Real-Time Analytics and Insights: AI-driven analytics provide real-time visibility into supply chain performance, enabling businesses to identify bottlenecks, inefficiencies, and opportunities for improvement. By analyzing data on key performance indicators (KPIs), such as on-time delivery rates, inventory turnover, and order fulfillment rates, businesses can make data-driven decisions to optimize supply chain operations continuously.

- Risk Management: AI enables businesses to identify and mitigate supply chain risks, such as supplier disruptions, geopolitical events, and natural disasters, by analyzing data from various sources and predicting potential risks. By proactively managing risks, businesses can minimize the impact of disruptions on supply chain operations and maintain business continuity.

Sustainability and Ethical Practices

AI plays a crucial role in promoting sustainability and ethical practices in the textile and clothing industry. Machine learning algorithms analyze environmental data and production processes to identify opportunities for reducing waste, minimizing energy consumption, and lowering carbon emissions. Additionally, AI-powered supply chain transparency solutions enable consumers to trace the origins of clothing items and verify compliance with ethical and environmental standards, fostering transparency and accountability.

Conclusion

Artificial Intelligence (AI) is driving innovation and efficiency in the textile and clothing industry, transforming design, manufacturing, retail, and supply chain management practices. By leveraging AI technologies, businesses can enhance creativity, optimize production processes, personalize shopping experiences, and promote sustainability and ethical practices. As AI continues to evolve, its impact on the textile and clothing industry will only grow, enabling businesses to adapt to changing consumer preferences and market dynamics, and drive sustainable growth and competitiveness.